In this article we look at the semi-silvered mirror, providing a guide to what it is for, and how it works

The semi-silvered mirror has been a vital feature of many single-lens reflex cameras since long before the digital age, but it is now more important than ever, not just with all DSLRs but also with Sony SLT (single-lens translucent) digital cameras.

A mirror is a reflective surface, with the reflective part usually formed from a very thin layer of metal. With SLRs it’s the reflex mirror that can have semi-silvered areas. By reducing the thickness of a silvered or metal-layered area on the mirror, a percentage of the light is not reflected up into the pentaprism and into the viewfinder. This enables the unreflected portion to be diverted down, beneath the mirror to a dedicated sensor for autofocusing.

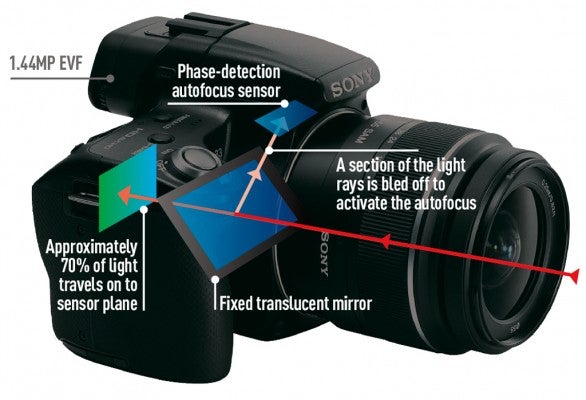

In the case of SLT cameras, the majority of the light passes straight through the mirror and, when the shutter is open, onto the sensor. The remainder is diverted upwards, to an autofocus sensor within the viewfinder housing.

A key advantage of SLT cameras is that as the mirror doesn’t flip up and down between exposures, so the metering and focusing sensors can continue their work while exposures are being made with no interruption. At the same time, the viewfinder view also remains constant. With reduced mechanical complexity there is less vibration and mechanical noise, and you can increase the sequential shooting rate of the shutter.

The idea of a fixed semi-silvered mirror is not new. Canon, for example, was using the idea in the 1960s with some of its professional Pellix SLRs.

A semi-silvered mirror sounds perfect, but there is one key weakness. If you divert some of the light coming from the lens, then the brightness either to the viewfinder or the metering or focus sensors – or even the image sensor, in the case of SLT cameras – is compromised. Nevertheless, the use of semi-silvered mirrors has been a great success in SLRs, DSLRs and SLT-type reflex cameras.