Bob Newman looks at the advantages and disadvantages of Sony’s recently developed curved sensor

When simple lenses are focused in the centre of the frame, the edge of the image can often be out of focus and blurred. Sony has manufactured a curved sensor to help correct for this

Recently, Sony announced that it had developed a curved sensor. The technique by which the company did this derives from wafer-thinning – the technology used to make backside-illuminated sensors. By etching away the back of the semiconductor wafer on which the sensor is formed, the backside of the photodiodes is exposed, resulting in greater sensitivity. As a by-product, the wafer becomes very thin and flexible, and needs to be bonded

to a further, rigid substrate to be sufficiently mechanically robust. In essence, Sony has made this substrate concave, so that the sensor itself takes on a similar form.

The main advantage of a concave sensor is that it provides some correction of field curvature – one of the most common optical aberrations suffered by lenses.

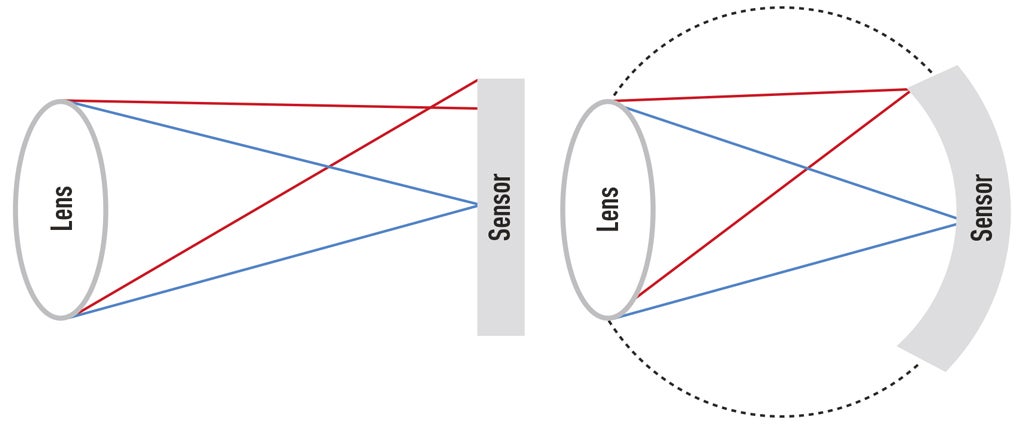

This is where the lens projects its image onto a section of a sphere, rather than a plane. If used with a flat sensor, the outer edges of the image are focused in front of the sensor, resulting in a blurred periphery.

While this effect has been sought after in some portrait lenses, by and large it is something that most photographers would rather do without. Thus, lens designers attempt to eliminate field curvature as much as possible. This usually results in additional elements in the lens design, making the lens larger and more expensive. If a lens is used with a sensor whose curvature matches the image that the lens projects, then these additional field-flattening elements are not needed. So the major benefit of Sony’s innovation is that it should be possible to make cameras with smaller and cheaper lenses.

Unfortunately, there is rarely such a thing as a free lunch, and the range of applications of the new sensor is limited to cameras with fixed lenses. Lenses don’t all have the same amount of field curvature, so to take advantage of the curved sensor it must be matched with the lens design. Today’s interchangeable-lens camera systems are designed for lenses that project a flat field. Putting a curved sensor behind those lenses would just replicate the blurred edge effect.

So, unless a new interchangeable-lens system is developed, with all lenses possessing the same curvature as the sensor, using more than one lens with such a sensor is a non-starter. Moreover, such a system would be unusable

with third-party and legacy lenses, so it’s unlikely that any manufacturer would make the R&D investment for a complete, stand-alone system.